Groove type compost turner

2. Applied materials: animal manure(chicken manure, cow dung, pig manure etc.); agricultural waste(straw, rice husk, greenwaste, woodchips etc); food waste, city sludge,

3. Land occupation small: one machine with multiple tanks, the depth of fermentation material is 1-1.8m, the fermentation output is large, the land occupation is small

4. Save labor costs: Optional remote control, high degree of automation, reduce the damage of fermentation gas to the staff

The main purpose and characteristics of the equipment

Groove type compost turner is one of the main supporting equipment of fertilizer machinery and equipment units. It is suitable for ground tank fermentation, and one-time turning and throwing saves time and energy. It is the core equipment for industrialized harmless treatment of animal husbandry, urban garbage, sewage and sludge.

The machine has reasonable design structure, high efficiency, low energy consumption, high degree of automation, convenient use and low cost. It is a high-efficiency model popular among users.

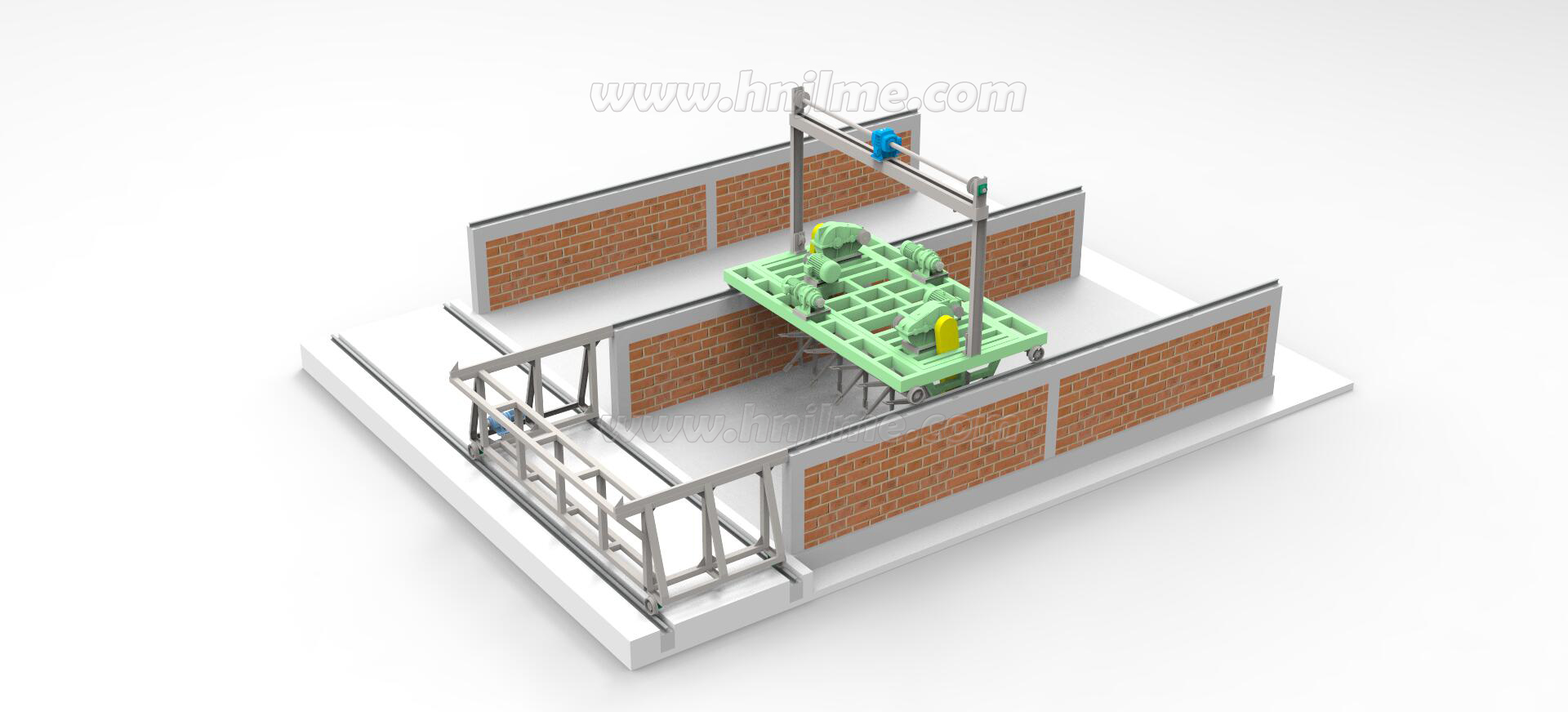

3D design demonstrition

Product parameters:

| Model | Turn speed(m/h) | Mix Power(Kw) | Turn width(mm) | Turn depth(mm) | Lift way |

| JLCFD-3000 | 100 | 22 | 3000 | 1000 | Hydraulic |

| JLCFD-4000 | 150 | 30 | 4000 | 1200 | Hydraulic |

| JLCFD-5000 | 200 | 37 | 5000 | 1500 | Hydraulic |

| JLCFD-6000 | 250 | 45 | 6000 | 1600 | Hydraulic |

Product structure & principle

1. Groove compost turner operated synchronously by 2 cycloidal pinwheel reducers, and the double sprocket chain drives the auger. The force balance of the components prolongs the service life of the components.

2. During the turning process, the walking speed can be adjusted at any time according to the density of the material. The walking adopts an electromagnetic speed-regulating motor to drive the worm gear reducer to run, and the working speed is at least 25mm/S------100mm/S. When it is necessary to return to the working position without load after flipping, the hydraulic pressure of the auger can be raised to 1m away from the material, and the walking speed is 100mm/S-150mm/S

3. The chuck on the auger shaft is specially used for fixing the agitator, and the screw contacts the material to reduce the load. The turning and throwing of the mixing knife can generally stir and throw the materials in the fermentation tank to a distance of 1.5-2.5 meters. Turning over the whole tank once is effective, the turning speed is fast, the stirring is even, and it has the function of breaking the material, so as to achieve full contact between the material and the air, so that the fermentation effect of the material is better.

4. The shifting car is composed of a motor, a cycloid reducer, a sprocket, a chain drive shaft, etc. It is a temporary delivery tool for changing the slot of the turning and throwing machine.