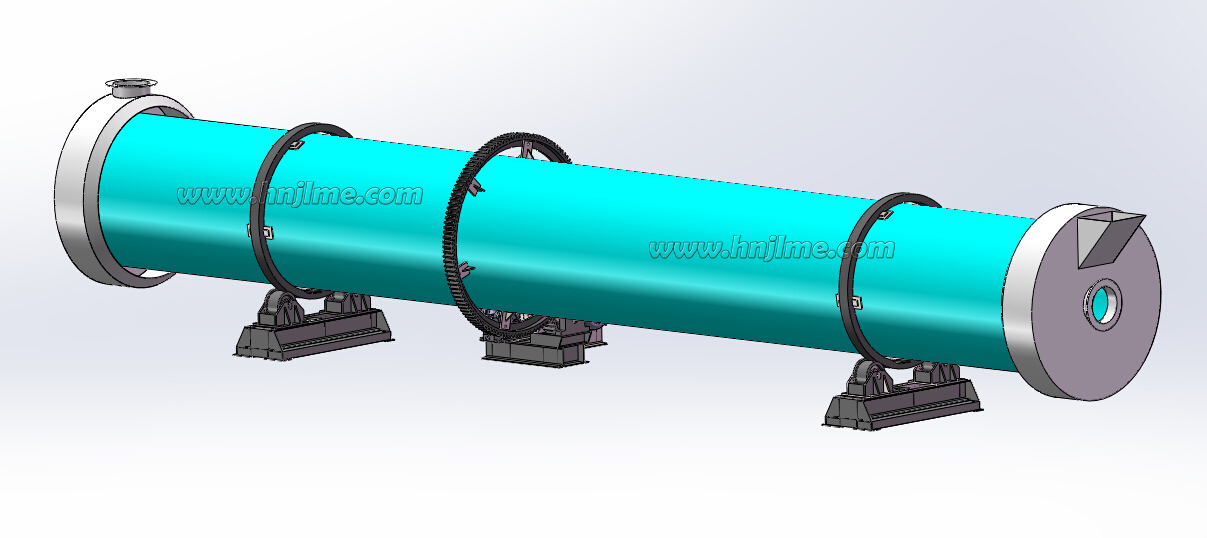

Rotary Drum Cooler

Production Capacity:1-40t/h

Power:37kw

Machine Valtage: 380V,50HZ, or customized according to your country electrical system

Function: always used for cooling materila after dryer, the material temperature is about 60 celsius degree after drying, so cooling material is necessary before packing the material after drying

Rotary drum cooling machine is used for cooling fertilizer with certain temperature and particle size in fertilizer industry.

The drum cooler is a cooling device composed of a rotating cylinder, It is mainly used to cool the high-temperature fertilizer granules after drying. The machine has simple structure and reliable operation. Used in cooling organic fertilizer & NPK fertilizer granules. The rotary drum cooler is one of the main equipment of the fertilizer granulation plant.

WORKING PRINCIPLE

The dry materials are sent to the cooler by conveyor or bucket elevator. The cooler cylinder is a rotating cylinder, which is slightly inclined with the horizontal line. Materials are fed in through the higher end, and heat carrier flows out from the lower end, and contacts with materials in counter-flow. Sometimes heat carrier and materials flow into the cylinder together. As the cylinder rotates, the materials move to the lower end due to gravity. When the wet materials move forward in the barrel, they receive heat from the heat carrier directly or indirectly, so that the hot materials can be cooled, and then are sent out through the discharge end. The inner wall of the barrel is equipped with a lifting plate. Its function is to lift the materials and scatter them, so as to increase the contact surface of the materials and the airflow, so as to increase the cooling rate and promote the advancement of the materials. The cooling body is generally divided into cold air and so on. After the heat carrier passes through the cooler, a cyclone dust collector is generally required to collect the materials in the gas. If you need to further reduce the dust content of the exhaust gas, it should also be discharged after passing through a bag dust collector or wet dust collector.

PRODUCT PARAMETERS

| Model | Power(kw) | Reducer model | Outlet material temp.(℃) | Inclind angle(grade) | Rotary Speed(r/min) | Output capacity(t/h) |

|

JLLQ-0808 |

5.5 |

ZQ250 |

room temperature |

3-5 |

6 |

1-2 |

|

JLLQ-1010 |

7.5 |

ZQ350 |

room temperature |

3-5 |

6 |

2-4 |

|

JLLQ-1212 |

7.5 |

ZQ350 |

room temperature |

3-5 |

6 |

3-5 |

|

JLLQ-1515 |

11 |

ZQ400 |

room temperature |

3-5 |

6 |

4-6 |

|

JLLQ-1616 |

15 |

ZQ400 |

room temperature |

3-5 |

6 |

6-8 |

|

JLLQ-1818 |

22 |

ZQ500 |

room temperature |

3-5 |

5.8 |

7-12 |

|

JLLQ-2020 |

37 |

ZQ500 |

room temperature |

3-5 |

5.5 |

8-15 |

|

JLLQ-2222 |

37 |

ZQ500 |

room temperature |

3-5 |

5.5 |

8-16 |

|

TDLQ-2424 |

45 |

ZQ650 |

room temperature |

3-5 |

5.2 |

14-18 |