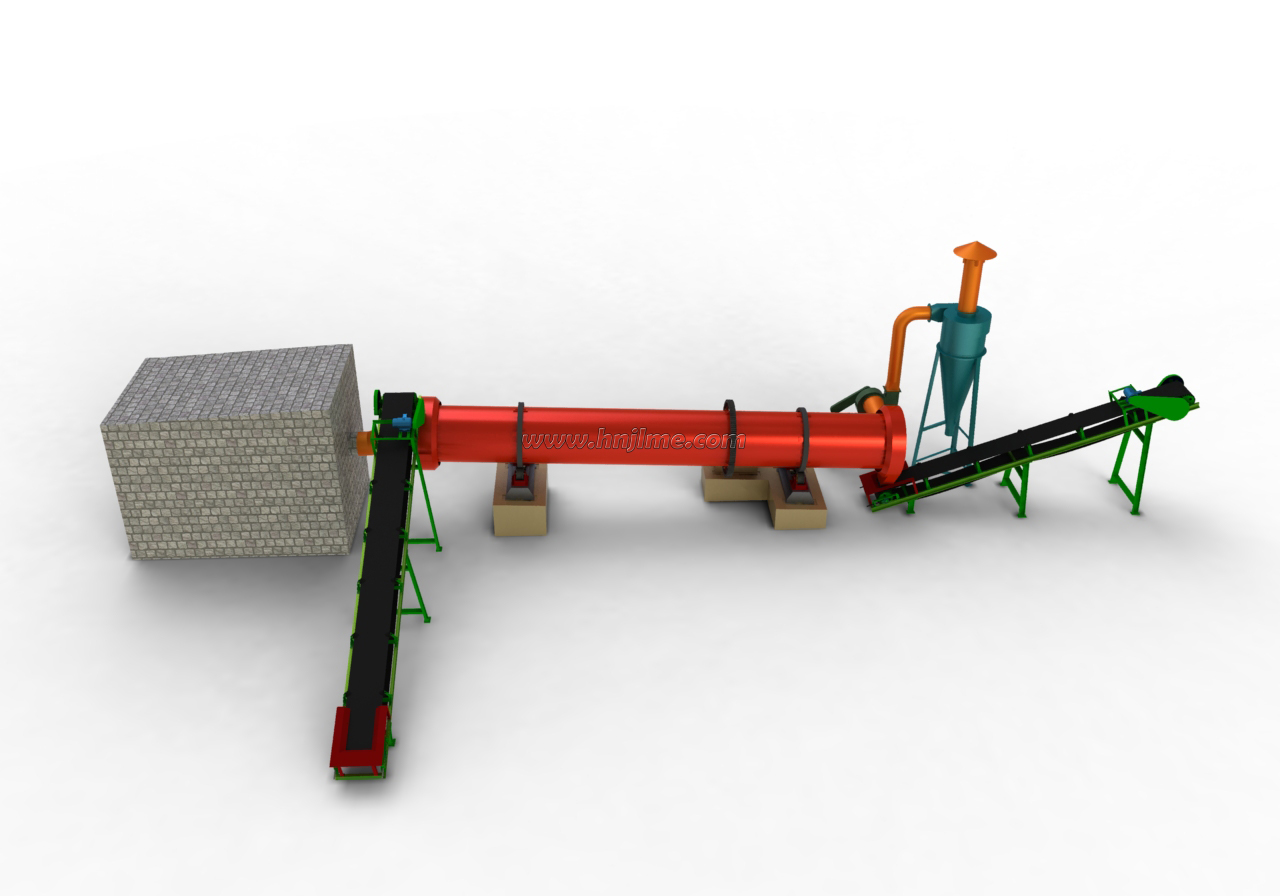

Rotary drum dryer

Production Capacity:1-40t/h

Power:37kw

Usage:The rotary dryer is a kind of industrial equipment used in fertilizer, metallurgy, chemical and other industries.

The rotary single-cylinder dryer is a device that drives the material through the rotation of the cylinder and the lifting plate set up to fully heat exchange the material with the high-temperature flue gas, so that the material can be dried. It has good drying effect, large production capacity, and high operating rate. , energy saving and environmental protection, easy operation and maintenance, and long service life of the whole machine.

PPLICATION SCOPE: Rotary single-cylinder dryer is widely used for drying river sand, bauxite, clay, shale, lump ore, slag, fly ash, etc.

WORKING PRINCIPLE:

The material enters the dryer through the feeding device. Since the cylinder rotates slowly in an inclined state, the material moves from the high end to the low end in the axial direction. During the movement, the lifting plate continuously moves the material upward in the circumference. Lifting, throwing and moving downward, so that the material and high-temperature flue gas can fully exchange heat until the material is dried to the specified requirements, and the dried material is discharged from the discharging device.

PRODUCTS ADVANTAGES

1. Compact structure, smooth operation, easy operation and maintenance, good drying effect, large production capacity and high operating rate;

2. Different forms of lifting plates are installed inside the cylinder according to the material conditions. The combination of circumferential lifting plates at various angles can greatly increase the heat exchange rate and shorten the drying time;

3. The supporting wheel support device and the frame of the supporting wheel supporting device have been welded as a whole and subjected to vibration aging treatment. After the welding stress has been eliminated, large vertical lathes and boring and milling machines are used for integrated processing and manufacturing to ensure the processing of each part. , matching accuracy and geometric tolerance, effectively improving the installation accuracy and reliability of the whole machine.

PRODUCT PARAMETERS:

| Model | Capacity(t/h) | Power(kw) | Inlet air temp.(℃) | Inclind angle(grade) | Rotary Speed(r/min) | Gearbox model |

|

JLHG-0808 |

1-2 |

5.5 | 300-400 |

3-5 |

6 |

ZQ250 |

|

JLHG-1010 |

2-4 |

7.5 | 300-400 |

3-5 |

6 |

ZQ350 |

|

JLHG-1212 |

3-5 |

7.5 | 300-400 |

3-5 |

6 |

ZQ350 |

|

JLHG-1515 |

4-6 |

11 | 300-400 |

3-5 |

6 |

ZQ400 |

|

JLHG-1616 |

6-8 |

15 | 300-400 |

3-5 |

6 |

ZQ400 |

|

JLHG-1818 |

7-12 |

22 | 300-400 |

3-5 |

5.8 |

ZQ500 |

|

JLHG-2020 |

8-15 |

37 | 300-400 |

3-5 |

5.5 |

ZQ500 |

|

JLHG-2222 |

8-16 |

37 | 300-400 |

3-5 |

5.5 |

ZQ500 |

|

JLHG-2424 |

14-18 |

45 | 300-400 |

3-5 |

5.2 |

ZQ650 |